What does our Thermography service offer you?

This service includes everything from a thermographic and visual control cabinet inspection to the identification of surface temperature anomalies (hot spots) and the associated diagnostics. You then receive a service report detailing any recommended courses of action.

-

Download

Your requirements

Identification of anomalies

relating to surface temperature

Inspection of control cabinets and drive technology

during ongoing production

Elimination of outlay associated with requirements arising from standards and legislation,

e.g. training, measuring equipment

Prevention of fire and accident risks

Improvement in classification

for fire insurance purposes

Trend development of anomalies

thanks to regular thermography

Our services

- Control cabinets, including air-conditioning units and switchgear (contactors, relays, impulse switches, pushbuttons, etc.) according to VDE 0670

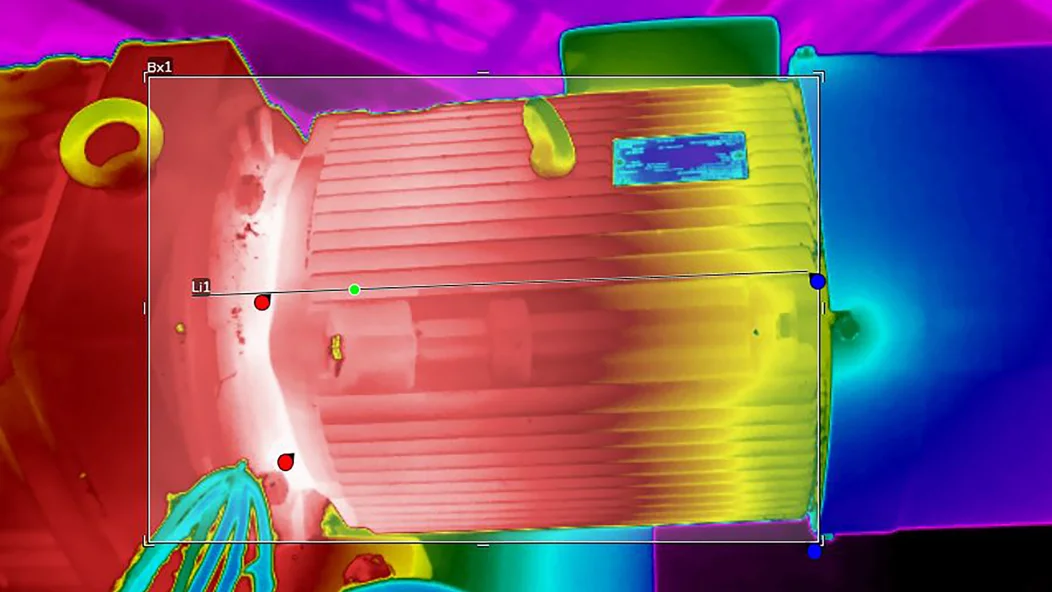

- Electric motors and gear units (hot spots due to bearing damage, insufficient lubrication)

- Low-voltage, medium-voltage, and high-voltage systems (transformer stations, machine control cabinets, medium-voltage distribution, basic supply systems, compensation systems)

- Oil, air, and water coolers

Diagnostics, thermal testing, and identification of anomalies relating to surface temperature (hot spots)

Visual inspection of the control cabinet in relation to pollution and the function of the fan

The measurement result readings are checked and documented in line with standards DIN 54191, DIN EN ISO 9712, and parts of DIN EN 16714.

Creation of a service report and, potentially, necessary recommended courses of action, taking the requirements of VdS 2859 into account

Your benefits

Examples of issues that can be detected through thermography

Bearing damage in the motor

Overheating of fuse in control cabinet

Overload of one gear stage in the gear unit

Contactor in the control cabinet with high transition resistance