When stacking pallets, make sure that the load is sufficiently strong and evenly packed. The load bearing capacity of the floor and the storage equipment must be observed, as they could collapse or collapse in the event of overload.

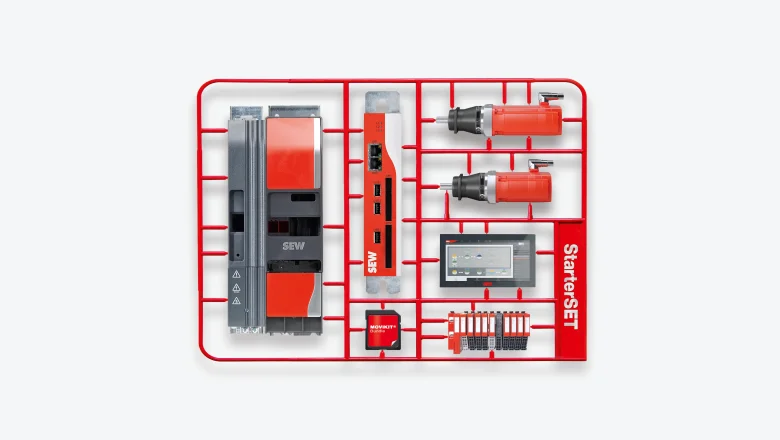

Your requirements

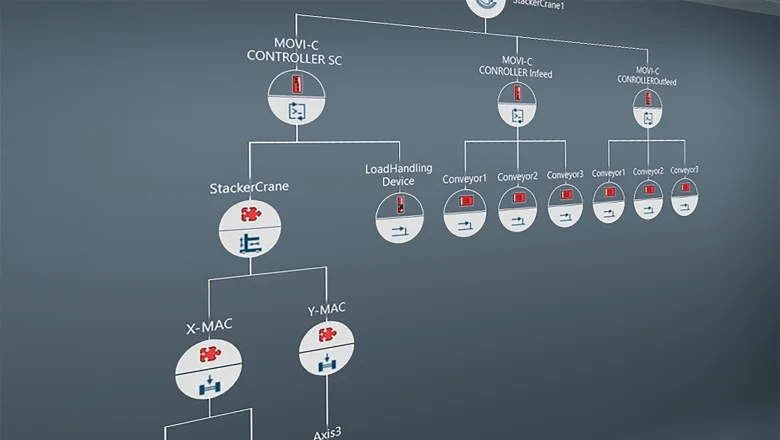

- Flexibility in the degree of automation: Full automation for autonomous machines

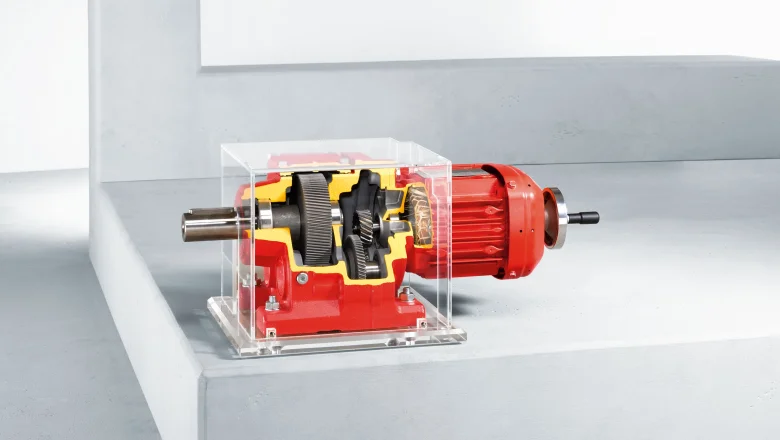

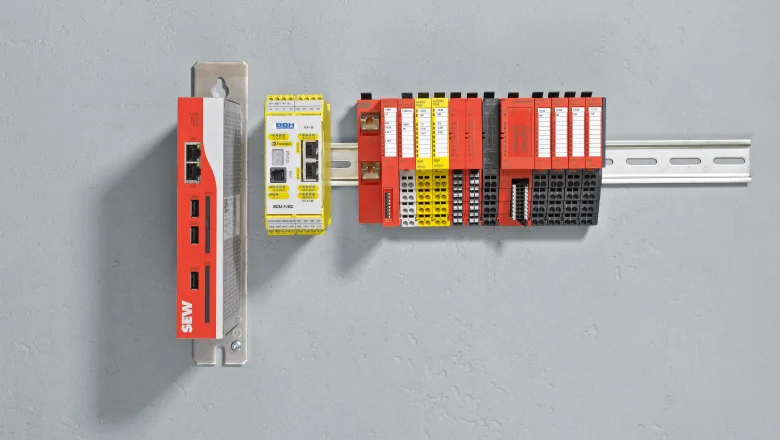

- Reliable technology

- Low maintenance costs