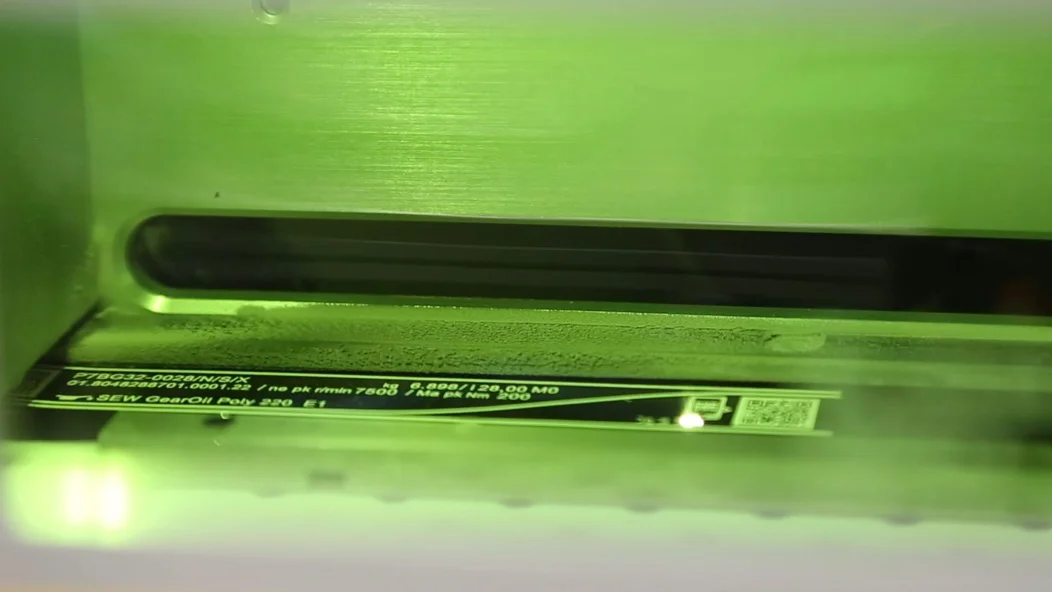

Then our PxG® planetary servo gear units offer crucial added value for all your requirements. All drives can be custom designed with appropriate service life, precision and performance.

A wide-ranging, scalable modular system – consisting of three performance classes, each in six sizes in one- to three-stage designs – offer all the flexibility you need:

- Performance class 5 for dynamic applications in intermittent duty with high switching frequency

- Performance class 6 for applications in continuous duty with high speeds

- Performance class 7 for applications in intermittent duty with restricted space