Retrofit

Project overview

Customer: Lindauer Bodensee-Fruchtsäfte GmbH

Sector: Beverage industry

Application: Pasteurization system

Solution: Customized drive solution for existing system

Benefit: Reliable and efficient production by minimizing system downtime and safeguarding spare part availability

-

Further data & documents available to download.

Modernization thanks to our Retrofit Service

Customer

Lindauer Bodensee-Fruchtsäfte GmbH is a cutting-edge family-run company with 60 years of experience in processing local fruits into fine products. The company produces over 90 high-quality juices, concentrates, and flavorings. It focuses on sustainability, fair prices for organic fruit farmers, and resource-friendly production. In addition to making first-class end products, Lindauer Bodensee-Fruchtsäfte also supplies the food industry.

Project description

Lindauer Bodensee-Fruchtsäfte GmbH was facing a significant challenge. Its pasteurization system, built in 1977, was showing considerable signs of wear. The original variable-speed gear units at the infeed and discharge ends of the system were worn and spare parts were no longer available.

Our specialist Retrofit Team developed a customized drive solution, which included a new compound gearmotor and all the necessary modifications. This solution proved to be more cost-effective and up-to-date than having the original supplier carry out a general overhaul of the existing variable-speed gear units. Lindauer Bodensee-Fruchtsäfte GmbH therefore opted for our modernization proposal.

Our innovative solution included:

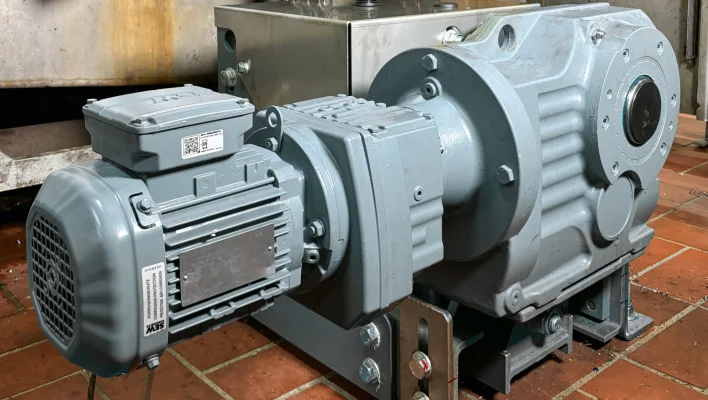

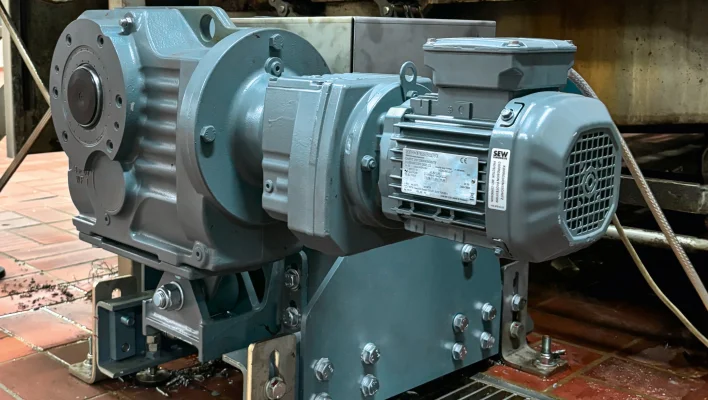

- New drive units with surface protection coating These ensure a longer service life and better protection against environmental influences.

- Declaration of incorporation and guaranteed spare part availability This ensures long-term operational reliability and minimizes future downtimes.

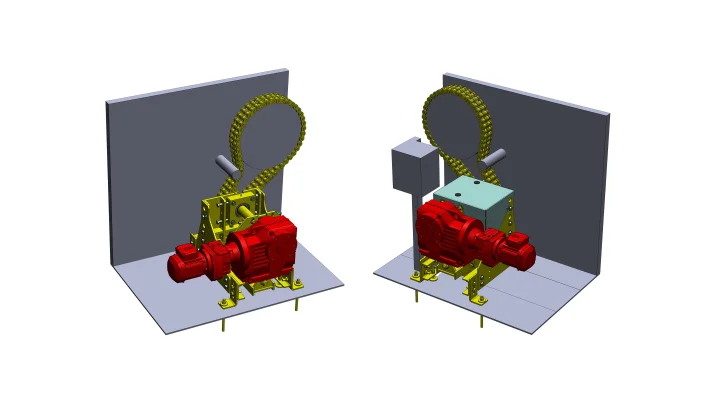

- Precise on-site measurements and CAD design These measures ensured smooth integration of the new drive units.

- Smooth integration of the new drive units The new units, each consisting of a compound gearmotor, motor scoop, plug-in shaft, bearing system, and pinion, were tailored perfectly to the existing system.

The drive units were pre-assembled at our service center and successfully completed a quality assurance inspection before being delivered. On-site installation was carried out by our experienced service fitter, with minimal idling time for the system. Thanks to this efficient modernization, Lindauer Bodensee-Fruchtsäfte GmbH can now focus entirely on juice production again.

The customer was extremely satisfied with the result and now benefits from a reliable and efficient production system that meets the company's high standards.

Other services and customer benefits

- Analysis of current situation and status recording We conduct a thorough examination of the existing system to document the current situation.

- Project planning and design We develop a detailed modernization concept based on the analysis of the current situation.

- Adaptation engineering of the system and the application We modify the new drive units to fit the existing structures precisely.

- Replacement of drive components and peripheral equipment We replace the old drive components with cutting-edge solutions.

- Replacement of peripheral mechanical equipment for application and system We replace worn or obsolete mechanical parts in the system.

- Startup After installing the new components, we start up the system.

- Project management We coordinate all project activities and ensure the project is completed on schedule.

Retrofit

is one of the many service packages we offer to cover the entire system life cycle.

Only with state-of-the-art machines and systems can you achieve the best possible productivity. Using our Retrofit Service to integrate our latest drive technology and drive automation will optimize your existing system's availability and process reliability.

Further information about our Retrofit Service