Are you keen to find highly flexible solutions that are in perfect harmony with your applications?

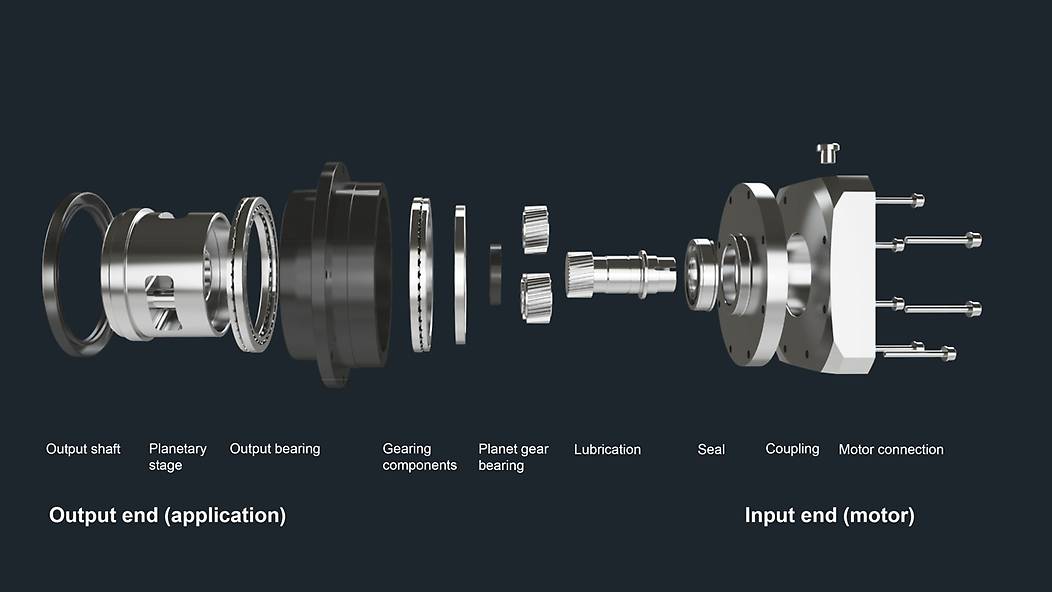

If so, we have just what you are looking for – our modular system complete with the modular product concept of our PxG®planetary servo gear units:

- Almost any combination is possible

thanks to several 1- , 2- and 3-stage gear units in a range of performance classes (P5 to P7) and a multitude of options such as various output bearings, rotational clearance classes, lubricants and seals.

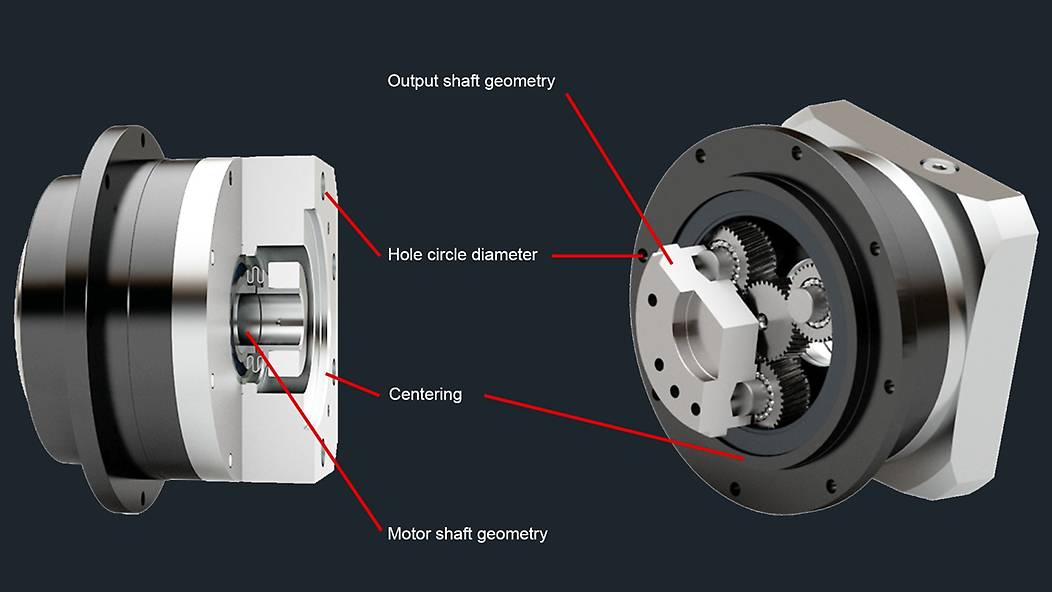

- Space-saving integration into any of your applications possible

thanks to high torque combined with a small installation space and various adapter designs. PxG®planetary servo gear units can also be integrated into existing systems with ease thanks to their geometric compatibility with the market standard. That’s how easy flexibility can be.