Retrofit

Project overview

Customer: Bruchniederung sewage treatment plant in Oberhausen-Rheinhausen

Sector: Waste water technology

Application: Impeller aerator

Solution: Retrofit Service replacing a drive

Benefits: Fast and dependable drive service ensures reliable continuation of water treatment

-

Further data & documents available to download.

Our Retrofit Service safeguards availability

Customer

In the 1990s, efficiency considerations led the municipalities of Oberhausen-Rheinhausen, Altlussheim and Neulussheim to merge their waste water disposal operations and form Abwasserzweckverband Bruchniederung. The sewage treatment plant was built in 1983, with startup following in 1984. It comprises an inlet tank, a screen with sand and grease trap, an aeration tank and a secondary clarifier. Two impeller aerators in the aeration tank supply sufficient oxygen. But that's not the only place where drives from SEW‑EURODRIVE are in use. Smaller gearmotors also power the screen, the secondary clarifier and the thickener/holding tank.

Project description

The drive suddenly stopped working

When Bernd Ehringer arrived at the Bruchniederung sewage treatment plant one morning in early December 2018, he was greeted by banging and clanking. "I heard the loud noises through the closed window of our control room and immediately knew something was wrong," says the waste water foreman. The noise was coming from the enclosure that housed the motor and gear unit driving one of the two impeller aerators in the aeration tank. Following initial investigations, Ehringer and his two colleagues discovered the gear unit had a major defect – parts of a gear wheel had broken off. That meant a new gear unit was needed. The supplier gave a delivery time of 21 weeks, which was too long for Ehringer and his team. The second impeller aerator was working reliably and the three spiral aerators in the center of the tank were also helping to keep the water moving. In the longer term, however, this would not be adequate to deal with the volumes of waste water.

Ehringer remembered going on a tour of SEW‑EURODRIVE as part of a sewage treatment plant neighborhood meeting. Hesitating only briefly, he grabbed the phone and called the technical customer service helpline in Bruchsal. "It's vital to act fast in such cases. I drove to the sewage treatment plant to appraise the situation," recalls Juri Braun from the field sales team of the Industrial Gear Units Service. Ehringer's fears were confirmed – the gear unit was damaged. Repairing it would have been uneconomical, so the unit was replaced.

The right size at the right price

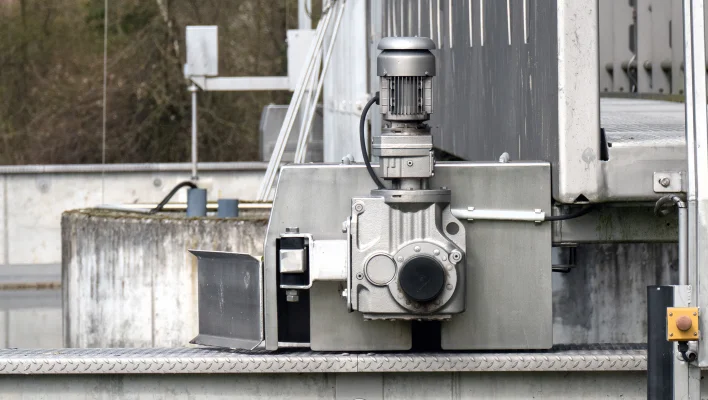

The defective drive was taken to SEW‑EURODRIVE's plant for large gear units, where its motor was removed. Both the coupling on the output side and the motor were in good condition and were to be retained, so the coupling was drilled open and fitted onto the new X3FS150/HA/B helical gear unit. HA stands for agitator housing – an X series model specifically for agitators and surface aerators.

Special technical features include a longer bearing center distance with bearing variants for moderate and high external forces, an integrated drywell gasket and a thermally optimized housing. The reinforced bearing system absorbs external forces more effectively, which means the gear unit does not need to be oversized.

With a nominal torque of 27 500 Nm, the gear unit at the Bruchniederung sewage treatment plant is dimensioned to ensure an appropriate level of safety for this application. The heavy-duty bearing system of the output shaft, which absorbs the high forces from the aeration process, also plays a role here. A gear ratio of around 36 was used to reduce the speed of the existing motor to the required 41 revolutions of the surface aerator. By reliably preventing oil from leaking out of the gear unit, a drywell gasket ensures the waste water is not contaminated. The gear unit also benefits from pressure lubrication to provide all rolling bearings and gearing components with an adequate supply of lubricant. An IEC motor adapter with integrated, torsionally flexible coupling connects the 55 kW asynchronous motor to the gear unit. Two adapter strips on the gear unit foot adapt to the existing connection dimensions.

The big advantage for the customer was that SEW‑EURODRIVE offered a solution that did not require the plant to be modified in any way. That avoided the outlay and uncertainty involved in adapting the design of the surface aerator and a possible loss of CE certification. In addition to preventing interface problems, the fact that SEW‑EURODRIVE supplied all the necessary drive components and incorporated third-party components also reduced the amount of assembly and installation work required at the sewage treatment plant.

Installation and startup of the entire drive unit took place in January 2020, and the impeller aerator has been working smoothly ever since.

Further services and customer benefits

- As-new repair with a 24-month warranty for defects covering the drive as a whole and components

- Quick Check with 12-month SEW functional warranty for the drive components checked and found to be OK

- Pick-Up and Delivery Service for fast pick-up and delivery of drive technology – including support from a service expert, if required, during removal and installation of drive components

- Examination with an inspection scope and oil analysis for preventive drive technology diagnostics and prevention of production downtime

- 24h Service Hotline (0800 7394357) for round-the-clock access to trained technicians and engineers

- Never far away with 33 sales and service sites all over Germany

Retrofitting

is one of the many service packages we offer to cover the entire system life cycle.

Only with state-of-the-art machines and systems can you achieve the best possible productivity. Using our Retrofit Service to integrate our latest drive technology and drive automation will optimize your existing system's availability and process reliability.

Further information about our Retrofit Service