-

By activating this video, Youtube will transfer data to the USA. More in our privacy policy.

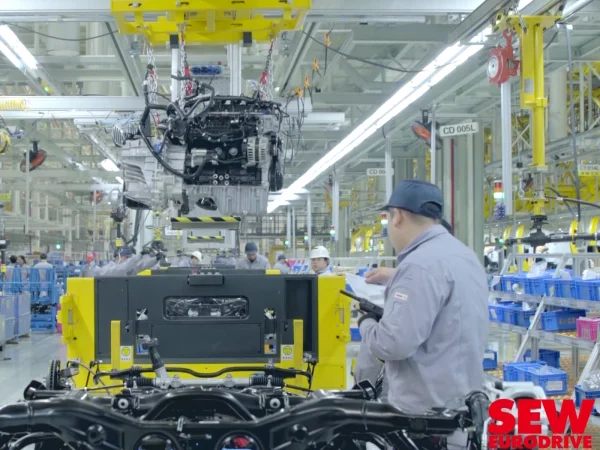

Innovative materials handling technology for efficient automotive final assembly

Jinkang is a subsidiary of the Chinese group SOKON and has one of the most modern final assembly lines in the new plant in Chongqing. With the MAXOLUTION® system solutions for the electrified monorail system and the skillet, SEW-EURODRIVE China has helped to ensure that production at the plant is state of the art from both a technical and a safety point of view. A successful reference project from the automotive industry.

The project at a glance

- Customer: Chongqing Jinkang New Energy Vehicle Co., Ltd, China

- Equipment manufacturer: AFT Shanghai Co Ltd (for electric monorail system), Miracle Logistics System Engineering Co, Ltd (for pusher platform)

- Location: Chongquing, China

- Industry: Automotive industry

- Application: materials handling technology for the complete final assembly of automobiles

Bird's eye view of the plant More info about our customer

- Jinkang is part of the Chongquing Sokon Automobile Co., Ltd group

- January 2018: Plant foundation in Chongqing

- December 2018: Start of production at the new plant in Chongqing

Innovative and safe assembly line with MAXOLUTION® solutions

Innovative and safe assembly line with MAXOLUTION® solutions For the cars of the future:

- low-maintenance operation of the system

- highest flexibility and ergonomics for assembly work

- State of the art safety technology for work under suspended load

- highest availability and easy plant engineering

- highest transparency of the plant technology / extensive diagnostic possibilities

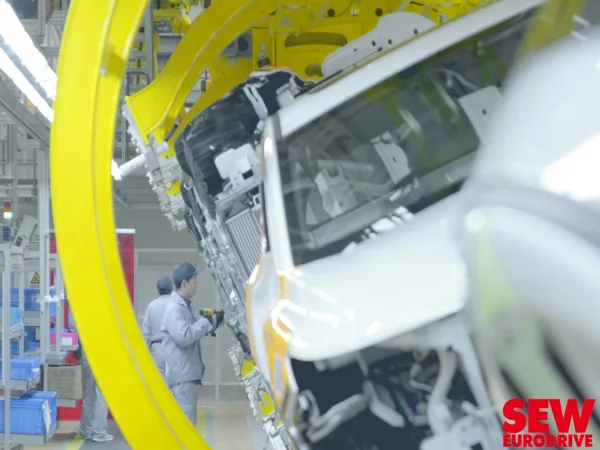

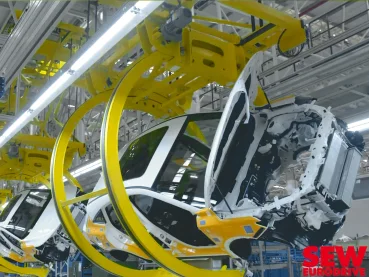

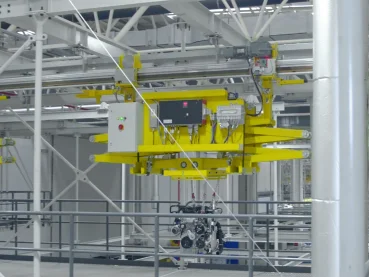

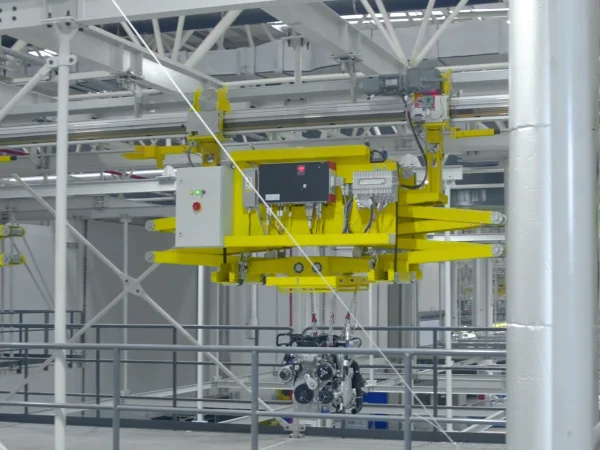

Heavy duty electric monorail for final assembly

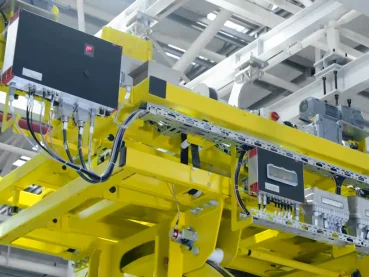

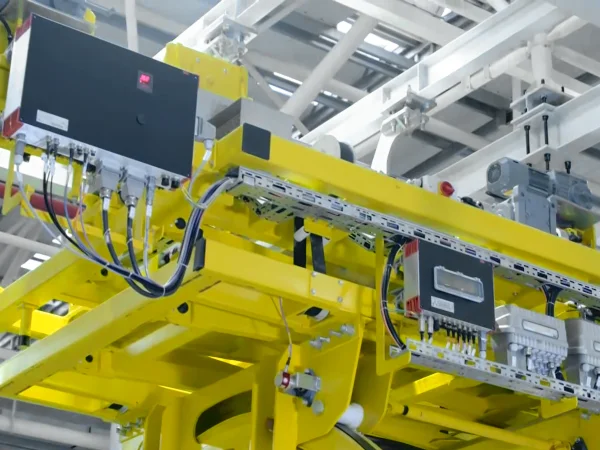

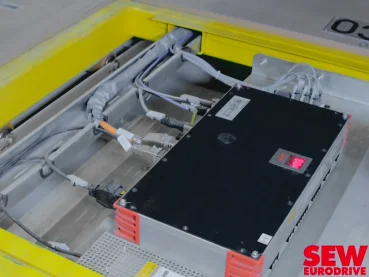

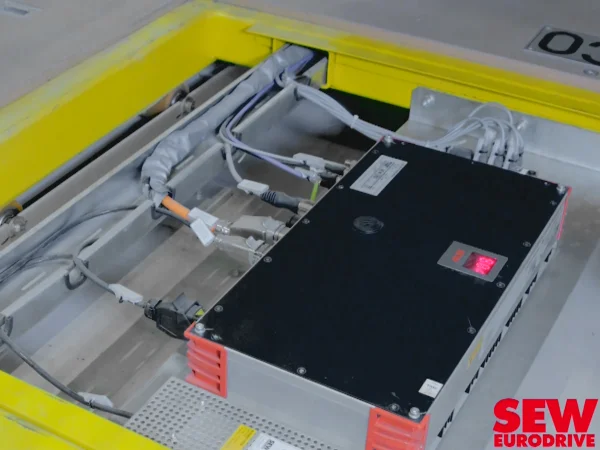

Heavy duty electric monorail for final assembly - Individual skillet equipped with the MAXOLUTION® solution for contactless energy transfer system MOVITRANS® for low-maintenance operation and maximum availability of the system.

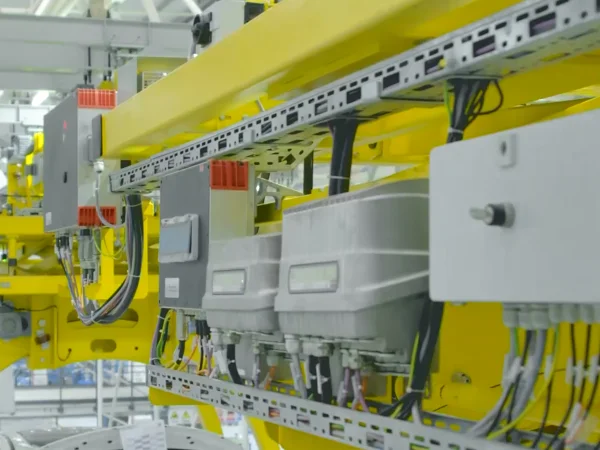

- Electrified monorail system (EHB for short) with the MAXOLUTION® system solutions:

- electrified monorail system for heavy loads

- light-duty electrified monorail systems

Efficiency and safety:

- Shielded WLAN communication via slotted waveguide (SHL) in all conveyor systems

- State-of-the-art safety technology, especially in the area of heavy-duty overhead conveyor systems (overhead work), is enabled by the high-performance MOVISAFE® safety controller of the type PFF-HM31 – with the safety functions:

- Safely limited speed (SLS) and

- Safely limited position (SLP) for travel and lifting axes

- Safe direction of rotation (SDI) for swivel axes

- State of the art safety functions for motion axis

- Safe communication with the higher-level system controller

- MOVIVISION® system software for simulation/emulation, virtual startup, visualization via human machine interface (HMI), permanent monitoring and real-time diagnostics

- Gear units and gearmotors: More than 2000 gearmotors from SEW-EURODRIVE are in use.

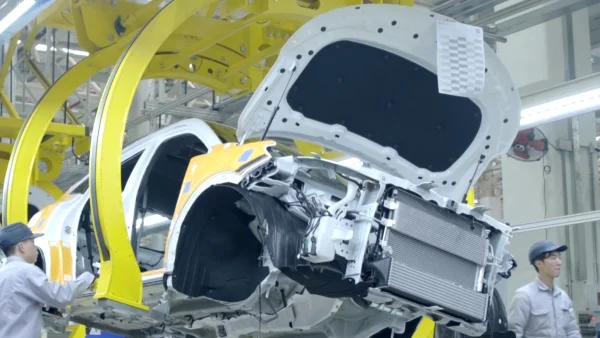

MAXOLUTION® heavy-duty EHB safety at the Chongqing plant

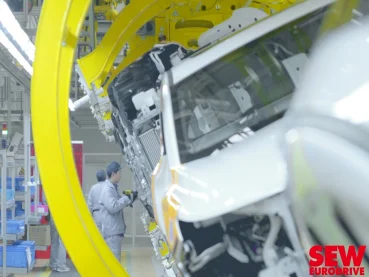

MAXOLUTION® heavy-duty EHB safety at the Chongqing plant - Maximum flexibility and ergonomics for the workers, as the body is presented at the optimum height and angle during the assembly process.

- High safety level during overhead work under suspended load, thanks to the innovative safety concept in particular with safely reduced speeds and position detection at all workplaces.

- System availability from day one thanks to the MOVIVISION® software tool, which is already used in the planning/engineering phase for simulation and emulation and for virtual startup and enables direct data download to the control components.

- Significant reduction of real startup due to prior simulated virtual startup.

- Production data is carried in parallel on the mobile conveyor system.

- Production speeds can be adjusted at any time at the push of a button.

- Diagnosis in real time.

Impressions of the project

Comments from our staff

"One of the most important benefits is the great ergonomics..."

"In my opinion, one of the most important advantages of the SEW-EURODRIVE drive system is its great ergonomics. In the past, our workers had to raise their arms to get the job done. Now, thanks to the tilt function, they can work in a posture that is much better for their health and reduces workload."

Mr. Chen Meisheng (Workshop Manager, Final Assembly Hall - Jinkang)

"The drive system is extremely flexible..."

"The drive system from SEW-EURODRIVE is extremely flexible. These advanced drive systems make it more convenient and flexible for us to produce new models or adjust our production lines."

Mr. Chen Meisheng (Workshop Manager, Final Assembly Hall - Jinkang)

"Different models on the same final assembly line..."

"Our products include different types of electric cars, including REEV (Range Extended Electric Vehicle) and BEV (Battery Electric Vehicle). SEW-EURODRIVE's solutions have enabled us to assemble different models on the same final assembly line. Overall, our cooperation with SEW- EURODRIVE is very smooth and trustworthy."

Mr. Chen Meisheng (Workshop Manager, Final Assembly Hall - Jinkang)

"Safety of equipment and employees is our top priority..."

"The safety of an industrial control system is an important part of the automotive industry. An intelligent and digitized system is essential for this. If a technical problem were to cause a production stoppage, we would have an enormous loss. Therefore, the safety of the equipment and employees during production and operation is our top priority."

Mr. Zeng Jian (Safety Engineer, Final Assembly Hall - Jinkang)

"... not only smart, but also super safe."

"The system solution from SEW-EURODRIVE is not only intelligent, but also super safe. It can effectively reduce risks in production, creating an advanced safety control system for the entire life cycle."

Mr. Zeng Jian (Safety Engineer, Final Assembly Hall - Jinkang)

"... a very safe, extremely reliable and environmentally friendly production"

"With the MAXOLUTION® system solution from SEW-EURODRIVE, the safety monitor is integrated into the system, allowing the entire system to be continuously monitored. This guarantees the highest level of safety for our employees and plants. Thanks to its proven technology, SEW-EURODRIVE has provided us with very safe, extremely reliable and environmentally friendly production. This allows us to improve efficiency and shorten the production cycle time according to our schedule."

Mr. Zeng Jian (Safety Engineer, Final Assembly Hall - Jinkang)

Products and Solutions used