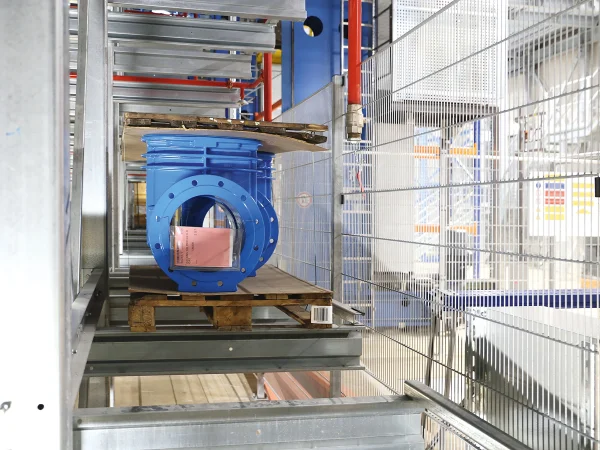

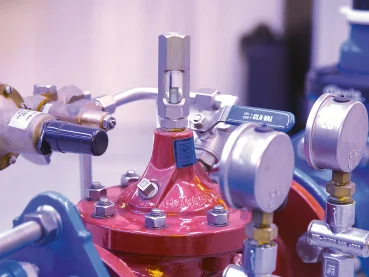

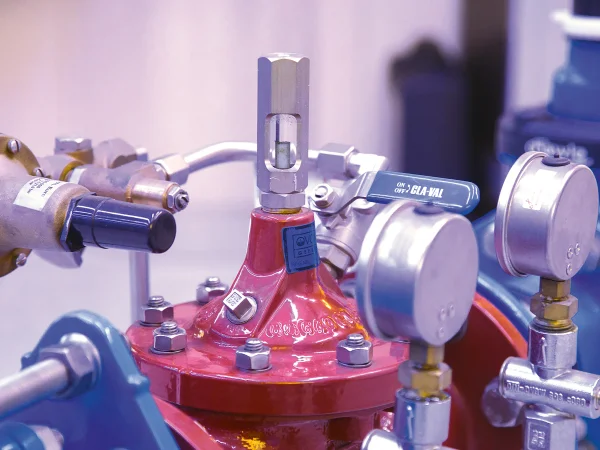

How our energy storage solutions are helping achieve a much better energy balance

Valves and fittings manufacturer Hawle has been able to achieve average energy savings of between 10 000 and 100 000 kilowatt hours (kWh) per year. The positive energy balance has been achieved by making greater use of frequency inverters, targeted heat recovery, and a comprehensive switchover to LED lighting.