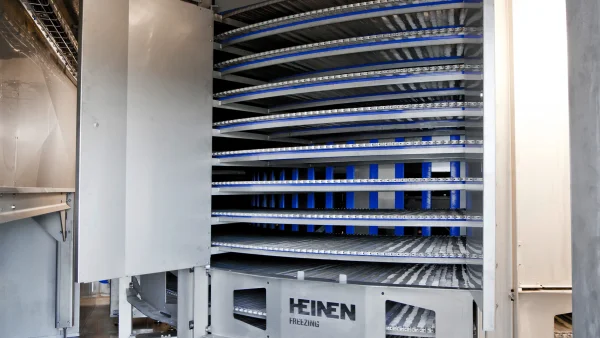

Heinen Freezing, a manufacturer of industrial pasteurizing, proving, cooling and freezing systems, uses planetary gear units from SEW-EURODRIVE in its equipment. The company thus benefits from a high torque but also complete solutions from a single source, an extensive service network and a modular system that enables short delivery times and high product availability.

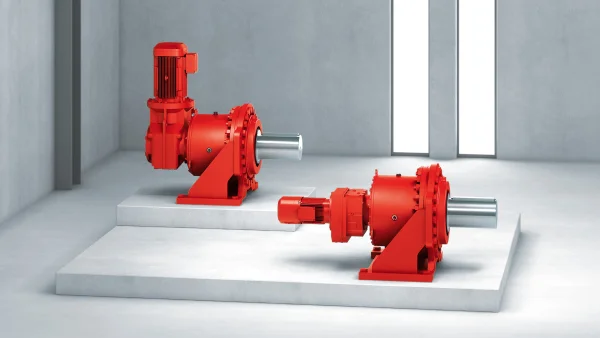

A planetary gear unit for a spiral freezer

The freshly baked rolls straight from the oven smell delicious, as always. Helge Pahl, Managing Director of Varel-based Heinen Freezing GmbH & Co. KG, explains the process that the products undergo beforehand: "The baked goods or bake-off products are frozen in an arctic a10 spiral freezer, for example, ensuring consumers can look forward to crispy, oven-fresh rolls at any time."

The torque required for the spiral freezer is provided by a planetary gear unit from the P series supplied by SEW-EURODRIVE GmbH & Co KG in Bruchsal. This series comprises eleven sizes covering the torque range from 25 to 630 kNm and is used to move heavy loads at low speed. As well as process engineering, the areas of application for these large planetary gear units include mining, hydraulic steel engineering and parts handling equipment.