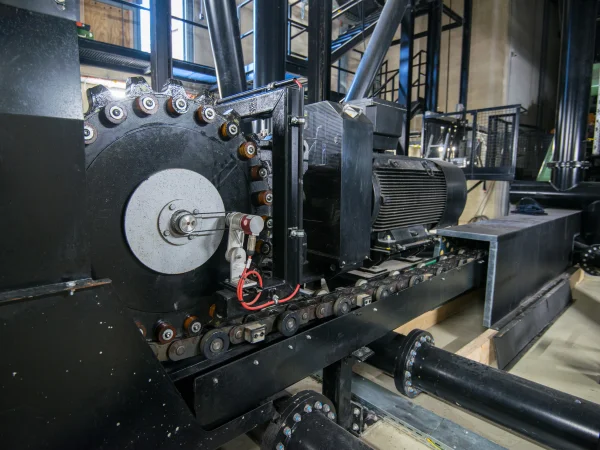

"The Oath of KÄRNAN" has three trains in operation simultaneously, each of them holding 16 passengers. One is in the air, getting pulses racing and providing an adrenalin rush against a magnificent Baltic backdrop on one of Europe's largest roller coasters. Meanwhile, the other two trains with passengers either boarding or exiting the ride are at ground level, where five additional drives from SEW‑EURODRIVE are in use. The drive units, each with a power rating of 22 kilowatts, use friction wheels to transport the carriages to the next station – the chain lift.

The vertical chain lift takes the carriages to the highest point of the roller coaster. It's a truly Herculean task! A drive power of at least 300 kilowatts is required to lift a fully occupied train vertically at a speed of several meters per second. When designing the gearmotor and frequency inverter, breakaway torques that were hard to determine in advance also had to be taken into account.

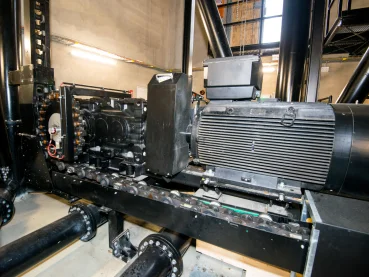

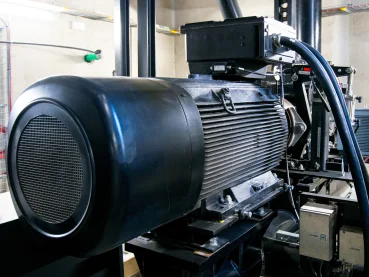

The drive specialists at SEW‑EURODRIVE decided to meet this challenge by incorporating a suitable energy reserve. A 400 kilowatt AC motor was the answer. There is no motor of this size in the company's own product portfolio, so the pragmatic solution was to use a third-party product – a motor from another manufacturer with an appropriate frequency inverter. The experts at SEW‑EURODRIVE made a point of being involved in the motor-gear unit combination's engineering, installation, startup, and subsequent maintenance.

An X3 KS 200 industrial gear unit was used for speed-torque conversion. This three-stage bevel-helical gear unit with solid shaft has a nominal torque of 79 kilonewtons. X series industrial gear units support virtually any mounting position and shaft arrangement. Equipping the drive solution geared to the customer's specific requirements with a dedicated gear oil cooling system provided the finishing touch.