Komptech builds mobile separating machines for handling biomass, gravel and waste. With its green efficiency program, the company implements a sustainable concept for reducing the maintenance and energy costs of its machines.

Komptech Umwelttechnik Deutschland GmbH develops, produces and sells environmental technology solutions. The company specializes in the development and production of machines for handling waste and biomass. The stationary or mobile machines (drum or star screen solutions) save energy while efficiently separating environmental materials for further processing and reintegration. At maximum performance, they achieve a throughput of up to 500 m³/h. Oelde is known for making the world`s biggest drum screens – with good reason.

Proven quality with a new concept

For about eight years now, market demand for machines with low operating costs has been growing. Because of the high maintenance requirements caused by periodic oil changes and hydraulic gear units, conventional machines are no longer up to date.

Komptech`s latest generation of drum screen technology represents a new concept for reducing energy, wear and maintenance costs. The machines are now completely equipped with electrical drives. The drum screen is driven directly by an electric motor using a friction wheel. This patented Wheelgrip delivers increased efficiency and is designed for well over 10 000 operating hours.

Of course, saving energy is not an end in and of itself. At the end of the day, what matters to the customer are the costs per cubic meter of material screened. Mobile machines can get up to 2000 operating hours a year. That is a large number. They can cut costs by up to 40 000 euros. That means this solution offers a return on investment after less than a year of operation.

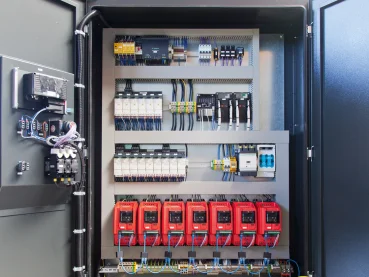

Komptech`s screening machines cover a large performance range using gearmotors from the DR.. series and MOVITRAC® LTP-B frequency inverters from SEW-EURODRIVE. The inverters cover all drive tasks up to a rated power of 160 kW. MOVITRAC® LTP-B is available with the IP55/66 degree of protection for a broad range of applications. An optional design with IP20 protection by enclosure is available for use in control cabinets.

To enable cost-effective use, the MOVITRAC® LTP-B frequency inverters for speed and torque control can be operated by synchronous and asynchronous motors without an encoder. In compliance with safety requirements, “Safe Torque Off” (STO) function according to EN ISO 13849-1 PL d is fitted as standard. The integrated control plate and function for automatically calibrating the physical properties of the motor simplify startup.

Project impressions

Customer requirements & our solution

Komptech wanted professional drive technology from a single source. „The deciding factors were the simple startup, the parameter module and the series that covers everything up to 160 W,“ explains Joachim Grundmann, SEW-EURODRIVE`s sales engineer in the Münster Technical Office.

„SEW-EURODRIVE`s service is first class. The DriveConfigurator makes it very easy to plan projects using Online Support. The plausibility check with a traffic light concept is especially user friendly.“

Components and solutions used

We'll be glad to assist you.

Do you need advice on a specific application? Just send us a message with your questions.

Inquire now