To ensure the continued availability of their existing drive technology, the operators of the Dachau water treatment plant commissioned SEW‑EURODRIVE to conduct preventive diagnostics (condition monitoring) on the three bevel-helical gear units in their intake pumping station.

The water treatment plant has been responsible for the reliable and round-the-clock treatment of community waste water for over 38 years. Among the equipment it uses are three screw pumps. They raise the waste water to ground level at the plant's intake station. Preventive diagnostics were conducted on the screw pumps in 2014.

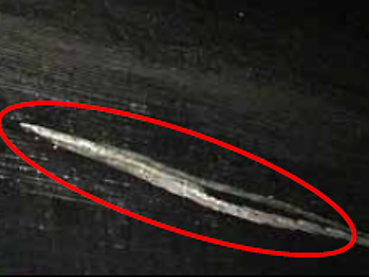

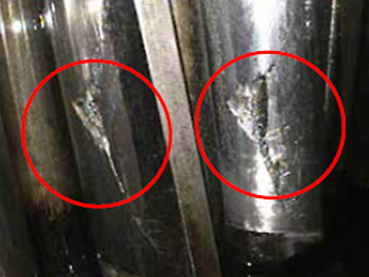

Putting the gear units to the test with video endoscopy

The systematic condition inspection was carried out using a flexible video endoscope. This probe can be guided through even small openings and provide razor-sharp images of the gear unit's interior. After the inspections, we were able to make recommendations for the inspected gear units based on the overall condition of the gearing components and the properties of the gear unit's lubricant. Two drives were already exhibiting significant wear indicators such as pitting and micro-pitting, which can eventually lead to larger edge ruptures and finally to a complete failure of the drive unit. The other drive was deemed non-critical because it still exhibited a low level of wear.

Repair or replacement as a result of the diagnostics

The water treatment plant then had to decide whether repairing their existing drive technology or replacing it was the more cost-effective option. SEW‑EURODRIVE’s comprehensive expertise proved indispensable in this decision. The Dachau water treatment plant decided to replace the existing components (non-SEW-EURODRIVE products) with industrial gear units from the X series. A three-level, bevel-helical gear unit design with a belt drive was chosen for the two new drives in the intake pumping station. The nominal output torque of each gear unit is 15,500 Nm.

Project examples

Project summary

With the installation of these drive units, the Stadtwerke Dachau public utilities company has acquired highly standardized industrial gear units that will operate reliably for many years. By obtaining all necessary drive components from a single source, the company will avoid interface problems and reduce the amount of assembly work required in the treatment plant. In addition, because of the company's close proximity to the service center in Kirchheim (near Munich), they can count on comprehensive customer service even after the drives are started up.

Components and solutions used

We'll be glad to assist you.

Do you need advice on a specific application? Just send us a message with your questions.

Inquire now