Dynamic, agile, intelligent, forward-looking, full of stamina, flexible, independent and considerate – everything employers are usually looking for in new employees. If Torwegge has its way, one such employee will soon be ensuring a better production climate in large sections of intralogistics.

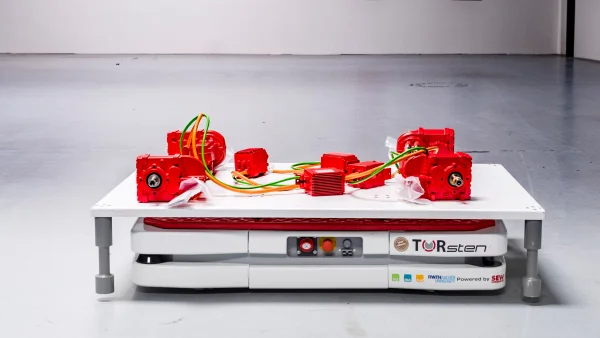

The new member of the operations team is called Torsten, and is an automated guided vehicle system that unquestioningly brings new products and tools to the workplaces of its human colleagues, or picks up pieces and takes them to other production cells. "Torsten enables us to interconnect production cells very flexibly," explains Dirk Jonat, Head of Project Management and Technology at Torwegge. He feels the advantages are clear. "We save our customers having to permanently install material flow technology and expensive conveyor lines."

In addition, Torsten is capable of acting independently of the overarching material flow if circumstances require. For example, it can travel in an elegant arc around any obstacles it suddenly finds in its path, while the speech module announces "I am going left." If this causes a long-term interruption to the procedure, another vehicle in the fleet can take over, and Torsten can begin the next task in the material flow plan. Managing Director Uwe Schildheuer provides an example: "If your satnav takes you into a street where someone is going to be working on a manhole cover for the next half hour, you don't sit there waiting, you look for an alternative route. A good satnav will do that for you and suggest a new route."

To ensure Torsten is able to plan independently and communicate with employees, it is equipped with a state-of-the-art speech module from Cognition Factory and an integrated navigation system specially tailored by RWTH Aachen University.