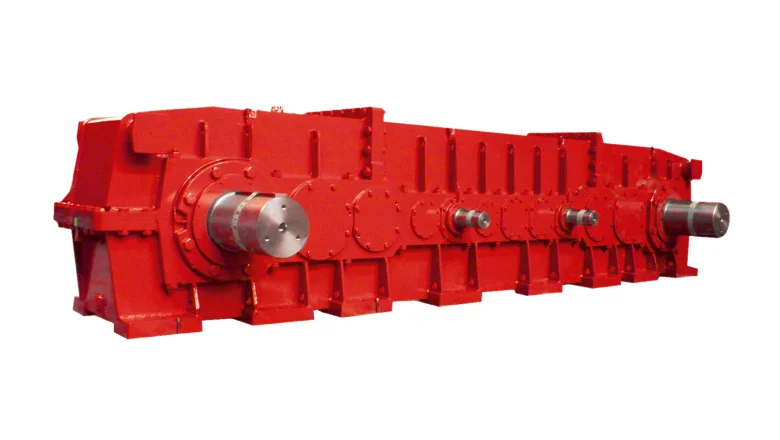

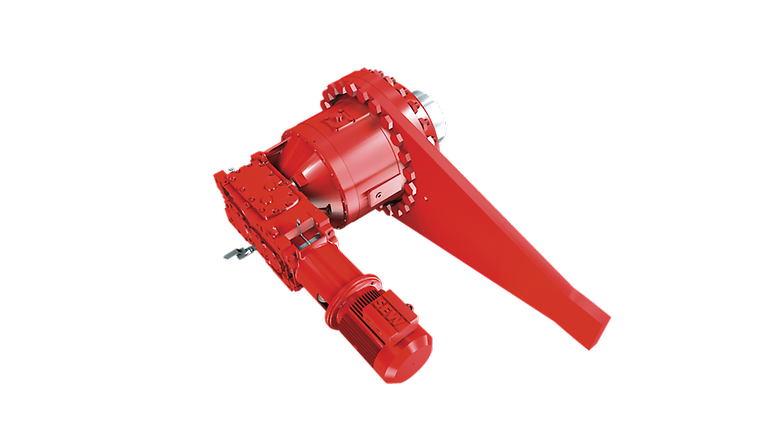

Did you know that the main hoist is a drive unit? It consists of gear unit, motor, coupling, brake and rope drum. It is used to lift and lower the containers. Heavy masses are moved and lifted to high altitudes. Consequently, high standards of safety and reliability apply. To meet these requirements and at the same time avoid oversizing the gear units, the gear units are designed according to the customer's specifications.

Your requirements

- Safety and reliability

- High torques

- Weight optimization

- Large center distance to avoid collision between drum and motor

- Increased bearing service life and housing strength to absorb high radial forces